summit crafts resin figure 3D prototype printing

Apr 11,2018 - resin figure 3d printing 3d prototype prototype printing summit crafts

In nowadays resin toy figure manufacturing industry ,3D printing technique is more and more important .it relate to future bulk production success.

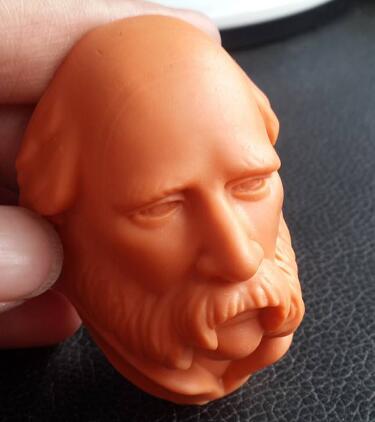

Prototyping

Toy manufacturers increasingly leverage 3D printing in their pre-production processes. By 3D printing prototypes, manufacturers can control the quality of the design and compare different versions while verifying that the toy parts fit well together. This verification enables them to identify potential issues at an early stage for a relatively low cost, thus leading to substantial productivity gains

After the 3D prototype came out ,we will do polishing to make it smooth,Once your surfaces are smooth, it\'s time to fill in undercuts and open loops that might "trap" the mold as well as just make parts harder to extract from the molds. You don\'t have to make the areas "flush" but it\'s a good idea to minimize them without compromising the design. You\'ll also want to add small details and details that didn\'t come through in the print. For example, areas where a bump map is used on your model, you\'ll have to recreate that detail with clay (epoxy sculpt in my case) or hard wax. This is also the stage where you can cover one part of a mating surface with clay and press it onto it\'s corresponding part on the model to create a "key" so that when the model is assembled it will fit together perfectly.

Then the master sample (prototype )is ready to be cast.The regular resin casting process can be started.

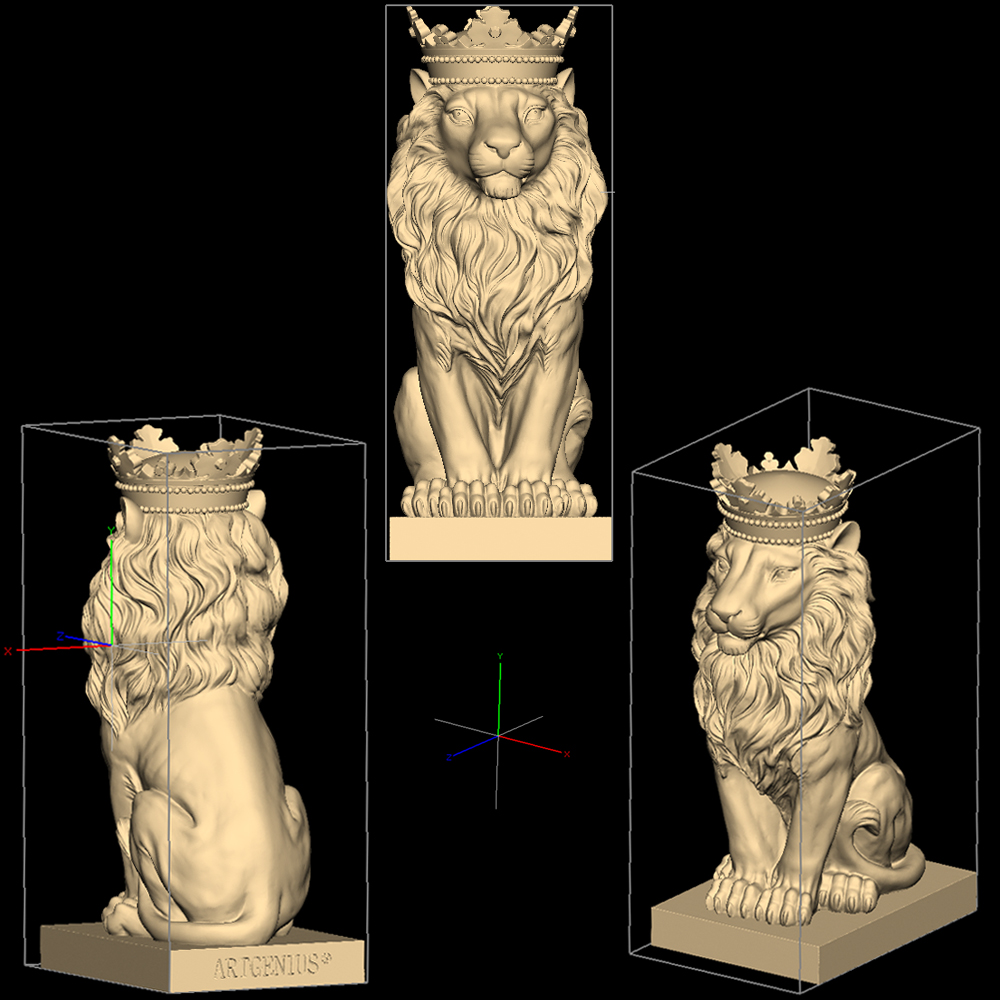

In summit crafts, we following the newest trend, we have the German 3D red wax 3D printing material, by using this material, the prototype is much more delicate and smooth, no need extra hand work, of course the cost of this material is also higher than regular material.